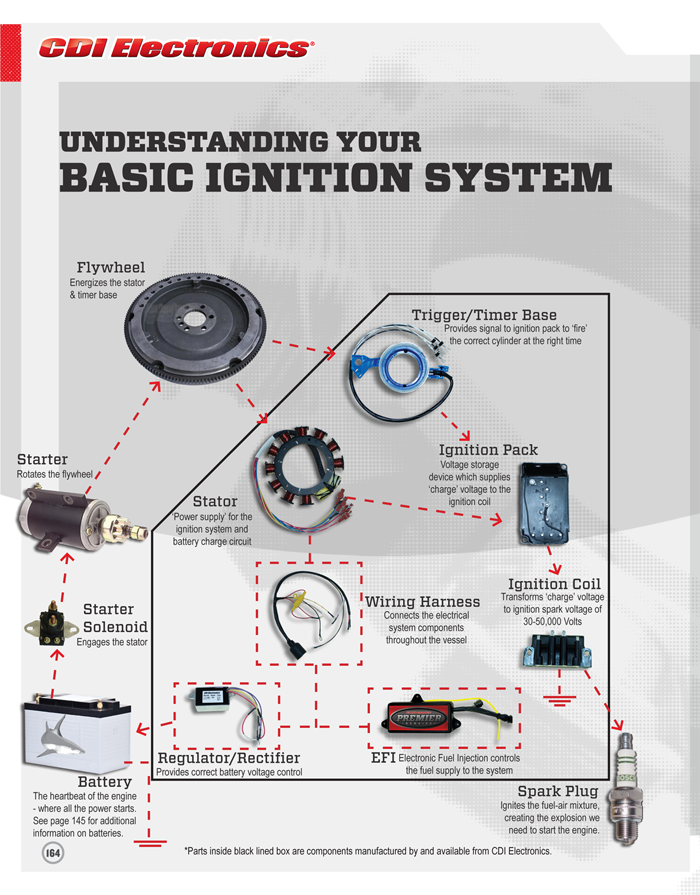

If you are having an ignition component problem, special equipment is usually required for testing most system parts such as stators triggers and power packs, so you may opt to let a qualified technician diagnose these problems for you instead. What is causing your motor to not start, cut out, run good to a specific RPM, overall run poorly? First make sure to check that timing is advancing properly and fully, there are no broken damaged or bare wires, nothing shorted out, no rogue arching spark around plug wires, etc. Outboard ignition systems are very different than those of the automotive type. Ignition systems can be the "tough" problems to figure out for the average person, and they can cause a very wide variety of symptoms.

Sure.check these links: Standard non oil injection fuel pumps | (Carb section coming soon!) My motor doesn't have oil injection, do you have a way that I can troubleshoot problems in that situation?Ī. If you dont understand the oil warning, your motor is doomed from continued operation if the oil injection system has failed. Regardless, when you hear the intermittant " " sound, always make sure you know the answer (low oil or no oil) before continuing to operate motor further.

When the oil tank is low, you have roughly 30 to 45 minutes running time before being empty. Oil injection on all outboards produces an intermittant beep when there is either a problem with your motor not getting oil, oil tank level sensor is bad, or your oil level in the tank is low. A steady continuous " beeeeeeeeeeeeeeeeeep" has to do with overheating. An intermittant " " sound has to do with oil injection. I have an oil injected motor and I hear the warning horn, but I dont know if it has to do with oil injection or overheating. Below are two methods to troubleshoot problems with them.

#Mercury 25 hp 4 stroke troubleshooting how to

We receive many inquires on how to test the Johnson/Evinrude VRO oil injection system.

#Mercury 25 hp 4 stroke troubleshooting trial

Upon diagnosis, just remember to check all three required elements before you simply start replacing parts by trial and error. Either stopped up carbs, weak or bad fuel pump, low or no compression on cylinder supplying pulse to fuel pump, a bad squeeze bulb, tank not venting, stuck anti-syphon valve on tank, loose fuel line connections, etc., could all be causing a problem you may be encountering. difference from cylinder to cylinder, then the problem would most likely be fuel related. If fire is good to ALL cylinders, and compression is within range showing no more than 15 lbs. This is why it is always a good idea to check the simple things first. For example: an anticipated fuel problem, can sometimes actually be ignition related, or even compression related. The Fuel system on an outboard, being a breed of its own, can confuse the average person during diagnosis. This page is designed to help you with the main topics where common problems occur. If any of the three are lacking, you will obviously experience a problem. Compression, fire, and fuel, are the three required elements for a motor to run. There is a golden rule to any gasoline powered motor whether 2 stroke or 4 stroke. BPS assumes no liability for loss, damages, or incorrect diagnoses resulting from usage of this information. The following is supplied by BPS as a brief reference guide only. Johnson Evinrude Mercury Mariner Force Chrysler Yamaha Mercruiser OMC Cobra Outboard boat motor troubleshooting and testing proceduresĭIY inboard outboard boat motor parts & accessories

0 kommentar(er)

0 kommentar(er)